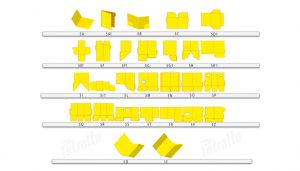

WHAT CAN THE MINI METRO FOLDING GLUING MODEL DO

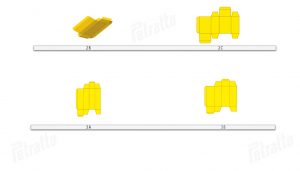

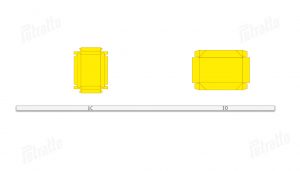

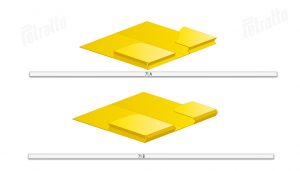

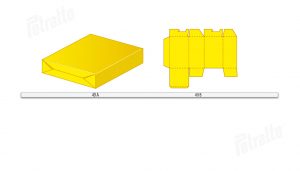

- Straight line boxes

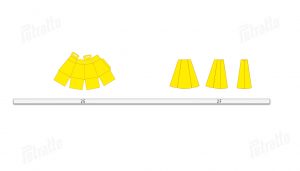

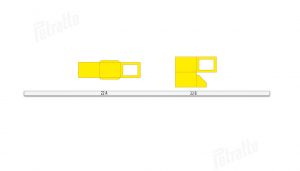

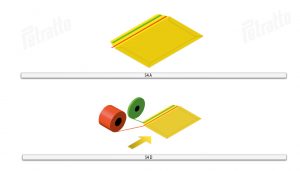

- Bands

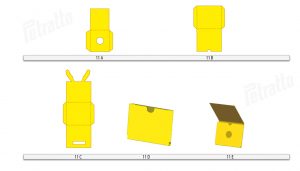

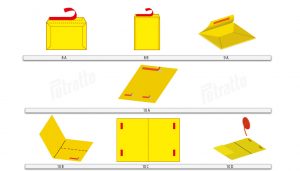

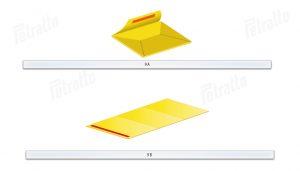

- Simple folders

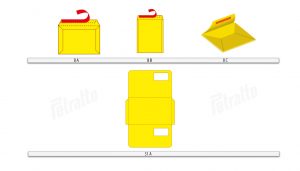

- Envelopes

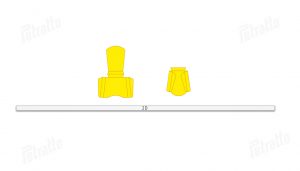

- Photo holders

- CD Wallet

- Double-sided adhesive tape application

MINI METRO is a kind of “platform” machine that can carry out simple converting and printing jobs in connection with a feeder.

Thanks to its open and modular structure, it has a great flexibility, without the burden and the complexity of dedicated machines.