METRO 78/105 folding gluing machine is a platform for the realization of special converting and printing jobs together, thanks to its open and modular structure and its great flexibility, without the burden and complexity of dedicated machines.

Its digital management system allows to interface with the other elements and attachments of the system. Jobs and sheet movement are controlled from the console. Metro grows up with jobs. Your jobs.

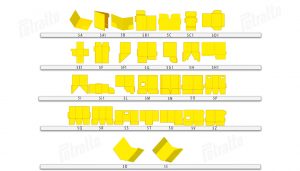

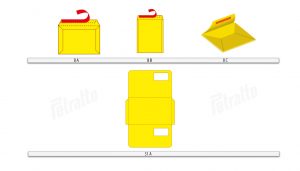

WHAT CAN THE METRO FOLDING GLUING MODEL DO

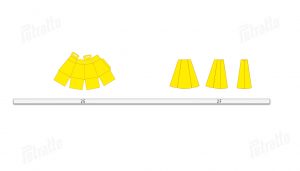

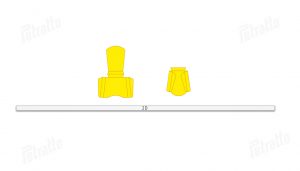

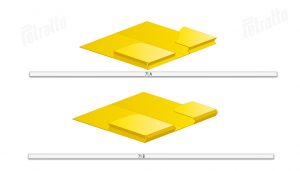

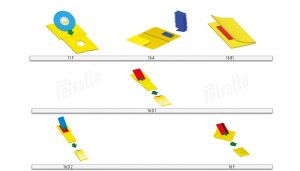

- Presentation folders

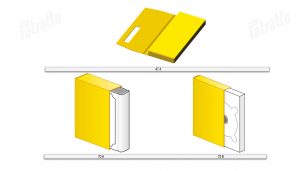

- Multimedia packaging

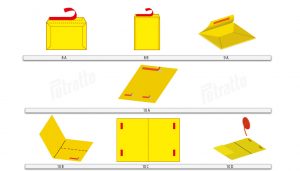

- Envelopes

- Multiple folders

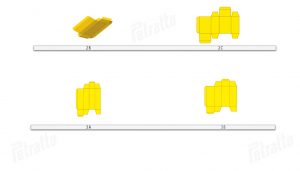

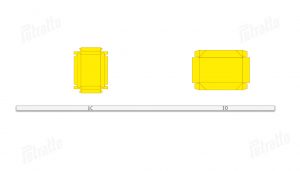

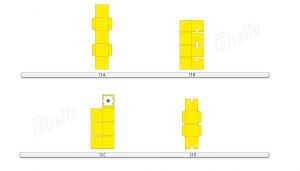

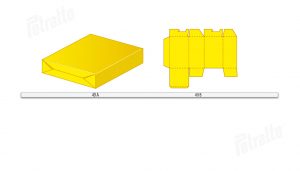

- Straight line boxes

- Cartons

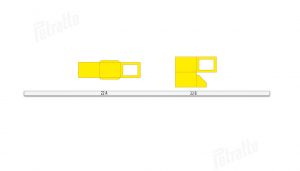

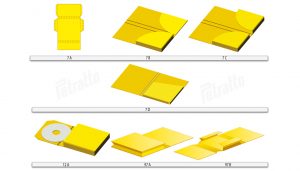

- Credit card wallets

- Airline ticket wallet

- Sleeves

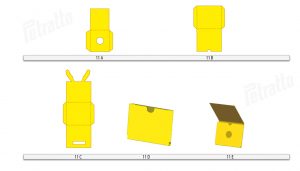

- Table tents – Greeting cards – Picture holders

- Reinforced edges

- Other foldings and gluings

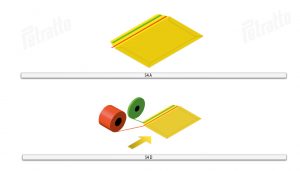

- Double adhesive tape application

- Remoistable glue application

- Credit card insertion (CD, booklets, envelopes)

- Linear boxes with insertion of instruction manuals

- Crash lock boxes

- Special boxes

- Concertina folders

- Start & stop perforation

- Creasing

- Scoring

- Label application

- Parallel foldings, Z folding, gate folds

- Mailing – Capacity folders

And many other applications